If you’ve ever had a client come back complaining that their Tape In Extensions are slipping out just days after installation, you know the frustration. It’s every salon owner’s nightmare — not only does it mean redoing the work, but it can also hurt your professional reputation.

So, why do Tape In Extensions slip? Is it the client’s fault for not following aftercare instructions? Or could the problem actually start in the factory — long before the hair ever reaches your salon?

In this article, we’ll uncover the real reasons behind slipping Tape Hair Extensions, focusing on five factory-controlled variables that often determine whether your extensions stay secure or start sliding. Plus, we’ll share a Zero-Slip SOP (Standard Operating Procedure) to help salons eliminate slipping once and for all.

What Are Tape In Extensions?

Before diving into the technical stuff, let’s clarify what Tape In Extensions are. These are pre-taped wefts of human hair that attach to natural hair using medical-grade adhesive. They’re loved by both stylists and clients for being lightweight, quick to install, and reusable.

The magic lies in the tape — a thin, invisible strip that bonds the extension securely without glue guns or messy keratin. However, when that tape doesn’t perform as expected, the entire system can fail.

The Common Complaint: Tape In Extensions Keep Slipping!

If you’ve been in the salon industry long enough, you’ve heard this one:

“My extensions started sliding after just one wash.”

Sound familiar?

While improper installation or poor aftercare can contribute to slippage, many times the problem originates before the hair even arrives at your salon. Yes — the factory plays a huge role in determining whether Tape In Extensions hold strong or not.

Let’s break down the five key factory-controlled variables that affect slip rates.

The 5 Factory-Controlled Variables That Cause Tape In Extensions to Slip

1. Tape Adhesive Quality

The adhesive is the heart of every Tape In Extension. It’s what bonds the extension to the natural hair. Factories that cut corners with cheap or low-temperature adhesives produce tapes that lose grip quickly, especially when exposed to heat or moisture.

High-quality tape adhesive should be:

- Heat resistant – able to withstand blow-drying and styling tools.

- Waterproof – should not break down after washing.

- Flexible yet strong – allowing movement without detachment.

If the adhesive formula isn’t balanced, slipping is inevitable.

2. Improper Tape Lamination Process

During production, the tape must be laminated onto the hair weft under specific temperature and pressure settings. If this process isn’t done correctly — say, if the temperature is too low or the pressure is uneven — the adhesive won’t fully bond to the base material.

Think of it like ironing clothes: if the iron isn’t hot enough, wrinkles remain. Similarly, without proper lamination, the tape won’t adhere properly.

A professional factory will maintain strict lamination protocols, ensuring even pressure and consistent temperature for long-lasting grip.

3. Silicone Residue on the Hair Weft

Here’s a sneaky culprit many stylists don’t even consider. During hair processing, factories often apply silicone coatings to make the hair feel smoother and shinier. But if the silicone isn’t completely removed from the weft root, it can prevent the tape from sticking properly.

Even the best tape in the world can’t bond to a surface coated in slippery silicone.

A responsible manufacturer will thoroughly de-silicone the weft roots before applying the tape, ensuring a clean surface for strong adhesion.

4. Environmental Factors in the Production Line

Humidity and temperature levels inside the production workshop can directly affect the adhesive’s performance. When tapes are laminated in humid conditions, moisture can interfere with the bonding layer, leading to weak adhesion.

Top-tier factories control environmental variables carefully — keeping humidity below 60% and ensuring clean, dust-free assembly rooms. This helps maintain adhesive strength and shelf life.

5. Tape Storage and Packaging Conditions

Even after production, the way Tape In Extensions are stored and shipped makes a big difference. If tapes are exposed to heat, moisture, or dust during storage or transport, the adhesive can degrade before it ever reaches your salon.

Proper packaging — such as vacuum-sealed or air-tight packs — keeps the adhesive fresh and ready for flawless application.

Zero-Slip SOP for Salons: How to Ensure Your Tape In Extensions Never Slide Again

Even with perfect factory production, salons must follow a precise Standard Operating Procedure to guarantee strong adhesion. Here’s a proven, step-by-step system used by top stylists to achieve zero-slip results.

Step 1: Prep the Hair Properly

Before applying Tape In Extensions, make sure the client’s hair is 100% clean and oil-free. Use a clarifying shampoo to remove product buildup and avoid any conditioners or serums near the roots.

A slightly rough surface gives the tape something to grip onto — think of it like painting a wall: primer first, paint later.

Step 2: Apply on Completely Dry Hair

Moisture is the enemy of tape adhesives. Always ensure both the client’s hair and the extension tape are completely dry before installation.

Even a hint of dampness can cause micro air bubbles, leading to eventual slipping.

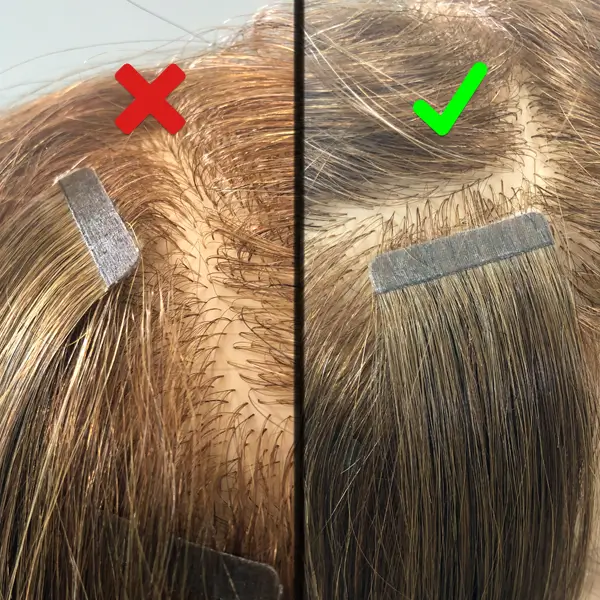

Step 3: Use Precise Sectioning

When applying, use small, even sections of hair between the tapes. Too much hair can prevent the adhesive from sealing, while too little can make it slip. The goal is a perfect sandwich — enough hair to support, but not block, adhesion.

Step 4: Apply Firm Pressure for 5–10 Seconds

Once the tape is placed, use a flat iron or extension pliers to press the bond firmly. Consistent pressure ensures full contact between both adhesive surfaces.

This step mimics the lamination process in the factory — sealing everything tightly.

Step 5: Enforce a 48-Hour No-Wash Rule

Advise clients not to wash or apply any products for at least 48 hours after installation. This allows the adhesive to fully cure and strengthens the bond.

Step 6: Use the Right Aftercare Products

Recommend sulfate-free, extension-safe shampoos and conditioners. Oils, alcohols, or silicones can break down the adhesive over time — leading to slips or separation.

Choosing the Right Factory: What to Look For

If you’re sourcing Tape In Extensions in bulk, choosing the right manufacturer is key. Here’s what separates professional factories from low-cost ones:

- Adhesive certification – Use of hypoallergenic, medical-grade tape.

- Controlled humidity – Ensures stable bonding conditions.

- Silicone removal process – Clean root surfaces before taping.

- Strong lamination pressure – Prevents delamination.

- Quality checks – Random pull tests to verify adhesion.

Ask your supplier detailed questions about their production process. A trustworthy manufacturer will be transparent about materials, adhesives, and testing standards.

The Role of Salon Education

Even with the best products, stylists need proper training. Offering a “Zero-Slip Tape In Certification” course to your team can dramatically reduce client complaints and boost retention rates.

Educated stylists = happy clients = stronger brand reputation.

Why Choose Jiffy Hair for Tape In Extensions?

At Jiffy Hair, we understand how frustrating it is to deal with slipping Tape In Extensions. That’s why we’ve engineered our extensions with premium American medical-grade tape, precisely controlled lamination, and clean, silicone-free wefts.

Every bundle is tested under strict temperature and humidity controls to guarantee maximum adhesion. Whether your clients have fine, thick, or oily hair, Jiffy Hair’s Tape In Extensions are designed to stay put — smooth, natural, and secure.

🎉 Special November Promotion

This month, Jiffy Hair is offering significant discounts on all human hair extensions, including our best-selling Tape In line! It’s the perfect time for salons and wholesalers to stock up and save big.

And if you’re attending Cosmoprof Asia 2025 in Hong Kong (November 12–14), come visit our booth! You’ll have the chance to feel our hair quality firsthand, see our anti-slip technology, and discuss partnership opportunities.

Conclusion

Slipping Tape In Extensions aren’t just an inconvenience — they’re a reflection of both factory precision and salon professionalism. Understanding the five factory-controlled variables gives you insight into where problems begin, while following the Zero-Slip SOP ensures flawless installation every time.

When salon expertise meets superior manufacturing, clients get what they deserve: long-lasting, natural-looking extensions that don’t budge.

So next time someone asks why their Tape In Extensions slipped, you’ll have the answer — and the solution.

FAQs

1. What’s the most common reason Tape In Extensions slip?

The main cause is poor adhesive quality or silicone residue on the weft, both of which prevent the tape from sticking securely.

2. Can clients wash their hair after getting Tape In Extensions?

Yes, but only after 48 hours. Washing too soon can break the adhesive bond and cause slippage.

3. Are Tape In Extensions reusable?

Absolutely! With proper removal and re-taping, high-quality extensions like those from Jiffy Hair can be reused multiple times.

4. How can salons prevent slipping during humid weather?

Use dehumidifiers during installation, and always store extensions in a cool, dry place to preserve adhesive strength.

5. Why should I choose Jiffy Hair Tape In Extensions?

Jiffy Hair extensions are factory-tested for adhesion strength, silicone-free, and laminated under strict temperature control — ensuring zero-slip results every time.

Jiffy Hair Factory is an experienced hair factory, we not only care about the quality of the wholesale hair extensions we provide, but also care about boosting your hair business.

If you want to get a reliable hair supplier, click “here” to send us an inquiry!